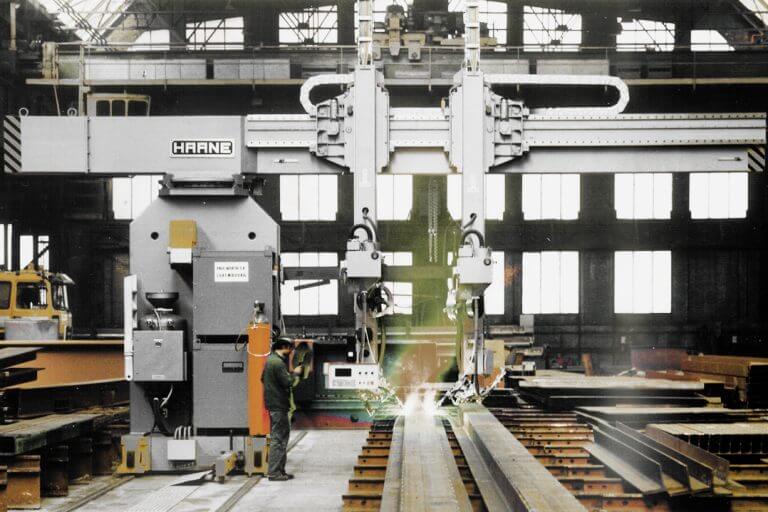

Welcome to HAANE welding systems

Welding systems made in Germany

HAANE welding systems is a private owned company active in mechanical engineering for the welding industry with many years of experience, but nevertheless a young and very flexible team of designers, welding specialists and a professional production workforce.

Our products? Solutions!

Thanks to our own in-house facilities, 3D-designing (SolidWorks) and manufacturing, we are able to realize customized solutions very quickly. Being future-oriented and open to new challenges, we will identify the best way how to contribute to the success of your projects.

We deliver consultant studies, equipment and turn-key units. Our assembly, start-up and after-sales crew with a great deal of inter-national experience operates worldwide.

Everything form one source

We accompany you from the welding task to the finished product:

- Concept development / Engineering

- Construction (3D, Solid Works / E-Plan)

- Production

- Assembly

- Quality control

- Commissioning

- Welding qualification of the product to be manufactured

- Production support

- Training

- After Sales Service

Everything under one roof, everything from one source. This is what makes us flexible and strong.