Mechanically or metallurgically clad pipes perfectly combine two properties: corrosion resistance and very good mechanical properties with a cost advantage over solid/pure CRA pipe materials.

In the case of mechanical LINED and metallurgical CLAD pipes, the circumferential weld on the double joint must have the same good anti-corrosion properties as the material inside the pipe.

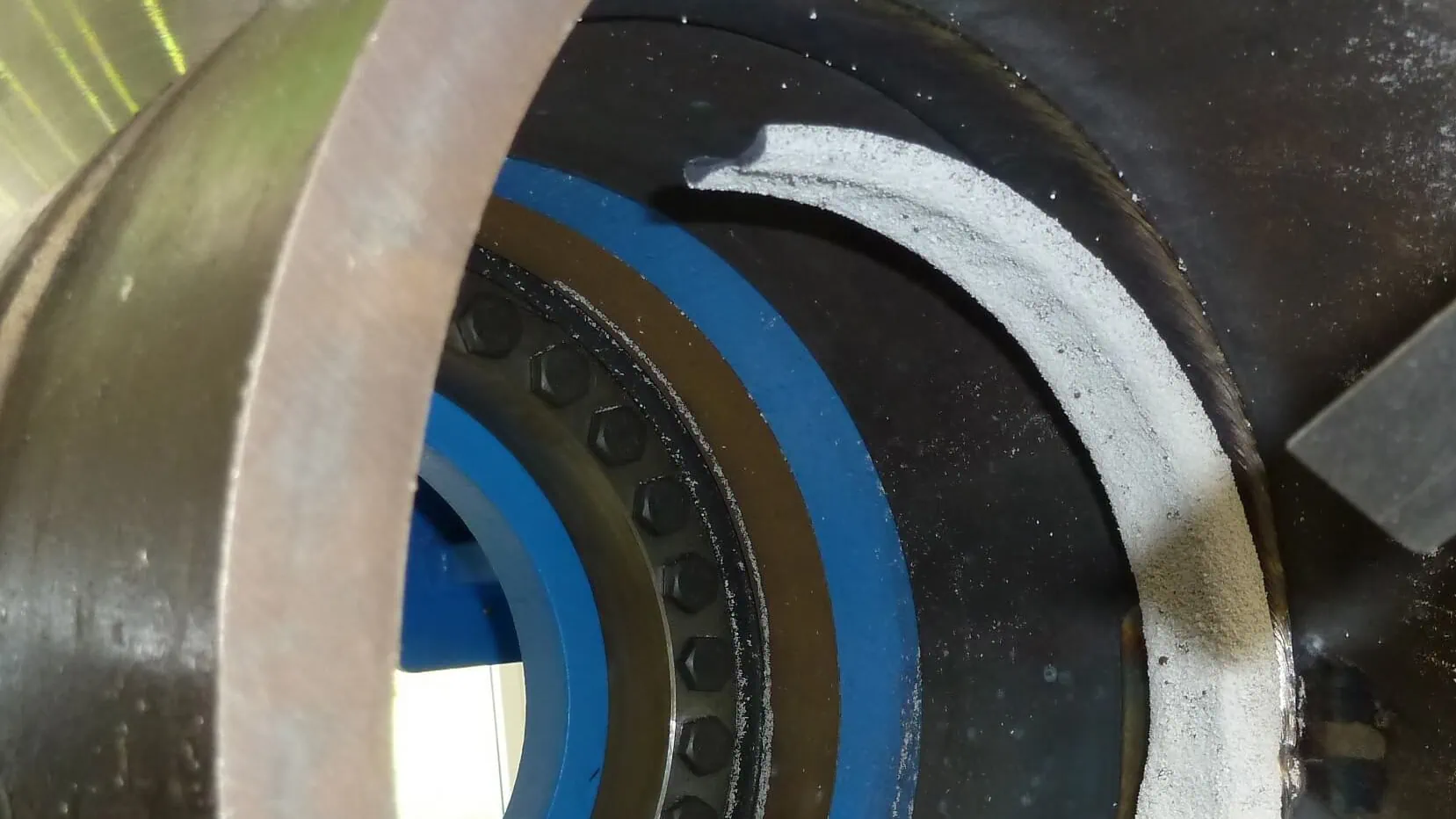

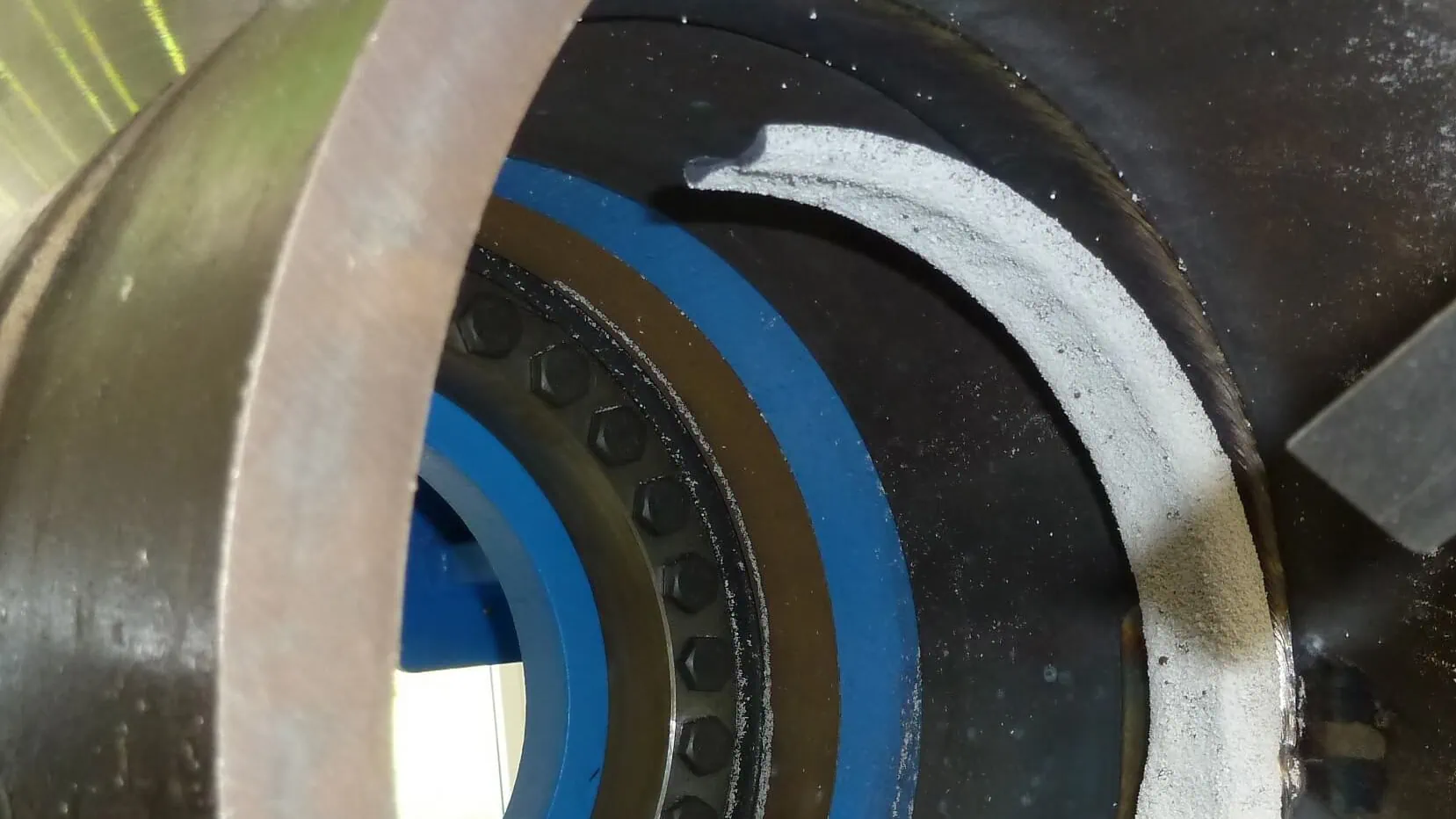

Electroslag strip welding (ESW) is a good process to fulfill this task. It can be used for pipes up to 12″ in size and 2 x 12,000 mm in length. Typical strip widths are 15/20/30×0.5 mm and typical alloys type 625, 825, 316.

Deposition rates of 6 – 12 – 24 kg/hour can be achieved and often only one layer is sufficient to meet the requirements.

HAANE welding systems supplies the entire system required, consisting of:

- Height-adjustable inner rail

- Pipe trolley with pipe positioner

- Welding/cladding equipment

- Belt unwinding and feeding system, also from large containers

- Welding flux circulation system

- Welding control unit, including welding parameter setting and control, camera monitoring system, data documentation for each individual clad pipe with transfer to a higher-level MES plant management level